mobile Differential Dynamic Scale Loop (mDSL)

The mobile Differential Dynamic Scale Loop (mDSL) is a tube blocking system designed for scale deposition measurements inside and outside the laboratory. The mDSL can be taken to customer site or into the field if the sample can't be transferred to your lab. With our transport case the mDSL can be moved safely to its operation site.

Mode of operation

The mobile Differential Scale Loop (mDSL) is a two pump system. The standard test procedure uses artificial, separated brines with a fix inhibitor concentration and a manual switch between brines and cleaning solutions. The typical applications are: test of blocking tendency, inhibitor performance and dissolver effectiveness.

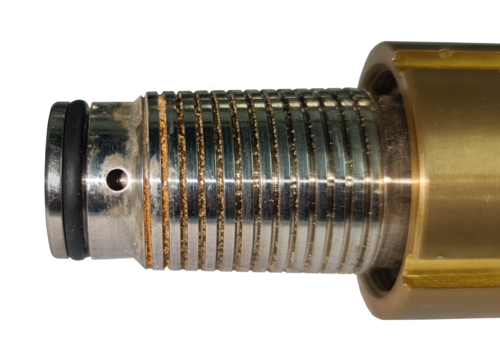

Heating cartridge - test capillary

The mDSL has a specially designed heating system for the test capillary. Instead of a tube coil, the capillary is in a pressure-tight cartridge system. This cartridge allows an easy opening of the coil, giving access to the precipitated scale particles. Because of this, the cleaning process is a lot easier.

Live water extension

For our instrument two extensions are available. Both allow the direct injection of real live water samples. For carbonate scale forming waters with dissolved gas or particles the sample can be injected pressurized and is drained in a second pressurized waste container. The sample will not depressurize in the whole process. For sulfate scale forming waters the injection line is additionally heated and the test capillary can be cooled for testing the temperature dependence of the scaling process.

Results from field tests as from the lab

Test conditions in regard to flow rates, temperature and pressure rating are comparable to the scale loops known from the labs. This allows you to obtain results in field tests that are comparable to those found in the laboratory.

Software control

Our software WinDSLm permits to control all parameters for the experiments, records all data and automatically stops the scaling test when scale formation is detected to ensure the capillary is not blocked.