Wax Flow Loop

Analysis of wax appearance and deposition in pipelines

The fully automated Wax Flow Loop by PSL Systemtechnik is a compact laboratory instrument to research deposition effects of waxes, paraffins and asphaltenes in pipelines.

Small sample volume - many test possibilities

Only 50 ml of sample amount are sufficient to come to conclusions about the efficiency and effectiveness of wax inhibitors.The Wax Flow Loop also provides the possibility to assay the efficiency and effectivenes of dissolvers. This feature allows you to execute Pipeline Restart Tests and Yield Stress Tests.

The Wax Flow Loop simulates pipeline conditions by a test capillary, which the sample is pumped through. During a test, the sample is heated to a set start temperature and pumped through the cooled/heated test capillary. Powerful heating and coolings systems reduce delays and allow for quick test execution.

The Wax Flow Loop is an instrument to examine wax deposition to the inner wall of the capillary via differential pressure and wax crystallisaion in the medium itself via differential temperature.

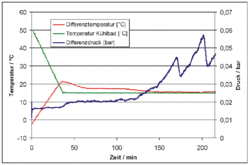

The differential pressure and -temperature are continuously measured and displayed as real-time diagrams on the monitor . This allows precise conclusions about development of wax depositions and crystallisation in the medium during a test run.

To maximise deposition effects and to shorten test-times a shock-cooling is possible.

Structure of Wax Flow Loop

Only 50 ml of sample amount are sufficient to come to conclusions about the efficiency and effectiveness of wax inhibitors.The Wax Flow Loop also provides the possibility to assay the efficiency and effectivenes of dissolvers. This feature allows you to execute Pipeline Restart Tests and Yield Stress Tests.

The Wax Flow Loop simulates pipeline conditions by a test capillary, which the sample is pumped through. During a test, the sample is heated to a set start temperature and pumped through the cooled/heated test capillary. Powerful heating and coolings systems reduce delays and allow for quick test execution.

The Wax Flow Loop is an instrument to examine wax deposition to the inner wall of the capillary via differential pressure and wax crystallisaion in the medium itself via differential temperature.

The differential pressure and -temperature are continously measured and displayed as real-time diagrams on the monitor . This allows precise conclusions about development of wax depositions and crystallisation in the medium during a test run.

To maximise deposition effects and to shorten test-times a shock-cooling is possible.

Flexible test conditions

The flexible Wax Loop offers various possibilities for experiments. So the test capillarycan be exchanged and thus be varied in length and diameter. This way, different approaches for test runs are permitted. Shorter test capillaries enable to observe effects in differential pressure, as well as in differential temperature. By changing the pump rate you can measure the deposition at different shear rates.

Experiments can be run with open or closed loop mode. In open loop mode the sample is lead to a waste container. The closed loop mode is suited to run long-time experiments. In this mode, the sample is pumped back to the sample container.

The integrated control-PC and the operation software WL_Control enable an easy usage of the instrument.

The software supports the definition and management of standardized experiment runs. So repeated and similar tests can be run time-saving and in quick succession. To clean the test capillary from remains of chemicals, it is possible to execute an automatic cleaning after every test run.

We can adapt the Wax Flow Loop to your requirements.