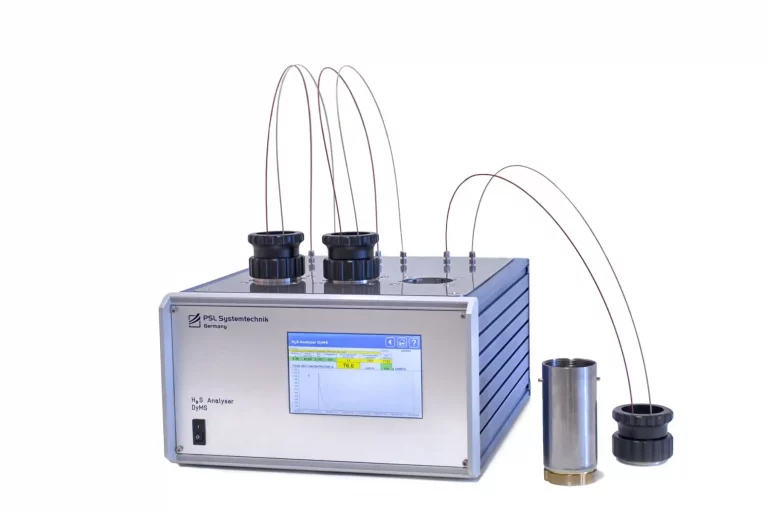

H2S Analyzer 320

Testing the hydrogen sulfide content in bitumen and crude oil up to 200 °C

The lab instrument H2S Analyzer 320 determines the hydrogen sulfide content and hydrogen sulfide concentration in bitumen, asphalt, crude and heavy oils as well as refinery products up to 200 °C. It is also suitable for the evaluation and optimization of H2S scavengers (additives).

The measuring method of the H2S Analyzer 320 enables precise measurements in the liquid and gas phase. Dissolved and escaping hydrogen sulfide, mercaptan, SO2 and inherent sulphur components are measured. The laboratory device provides very accurate and reliable results within the entire measuring range.

The H2S analyzer covers a wide emission level scale from 1 to 10,000 ppm hydrogen sulfide in the liquid phase and up to 1,000 ppm in the gas phase.

All important features of H2S Analyzer

- Measurement of hydrogen sulfide, light mercaptans, SO2 simultaneously in liquid and gas phase

- Measures dissolved and evolving H2S

- Temperature range +30 °C up to +200 °C

- Two storage container

- Portable test unit - can be used at site

Application Areas of H2S Analyzer 320

For bitumen, asphalt, crude, heavy oil and other refinery products

Evaluation and optimization of H2S scavengers (additives)

Quality control

Short story about H2S Analyzer

The test methods for bitumen, asphalt and heavy fuel oils used up to date are in general not giving reliable data, take a long time or are very expensive. Thus providing only insufficient solutions for requirements of most laboratories. The inadequate reliability of these test methods implies a big risk for health, safety and environment.

The need for reliable test methods has increased over the past years. The reduce of limits for H2S content in bitumen and heavy oils reinforced this development additionally. To meet this increased demand Clariant developed the DyMS method to measure H2S especially in bitumen. PSL moves the patent pending method into a laboratory instrument.

IN USE WORLDWIDE

Used by Leading Labs

Measuring Principle of H2S Analyzer

The measuring principle of the H2S Analyzer 320 is based on the DyMS method. The instrument has one – optionally two – storage containers and a measuring container in which the samples are constantly stirred and kept at a temperature of up to +200 °C. The sample is pumped into a measuring container – enriched with a high-boiling solvent – and constantly stirred. The sample is pumped into a measuring container – enriched with a high-boiling solvent – and stirred continuously.

The hydrogen sulfide is released by injected nitrogen. The mass transfer is improved and hydrogen sulfide can be better detected compared to other methods. Inert nitrogen prevents the oxidation of hydrogen sulfide. Finally, a special sensor measures the hydrogen sulfide concentration.

Measure H2S in the liquid and gas phase

The H2S Analyzer 320 (DyMS) measures dissolved and evolving hydrogen sulfide, mercaptans, SO2 and inherent sulphur components in bitumen and asphalt, a wide range of crude oils and refinery products under temperatures of up to +200 °C.

The instrument provides very accurate and reliable results within the whole measuring range. The H2S Analyzer works for a wide range of emission levels from 1 to 10,000 ppm hydrogen sulfide for the liquid phase and up to 1,000 ppm in the vapor phase.

Benefits of H2S Analyzer

With the H2S Analyzer you reduce scavanger treatment costs. You save development and measuring time compared to the actually used test methods. Your project costs reduce accordingly.

Testing of blending and with scavanger treated samples will get you much more accurate results over the measurement range.

It fulfills the needed stringent conditions for check heavy fuel oils, bitumen, asphalt for specific plant and storage conditions in realtime. Scavanger treatment can be optimized, adjusted to your application and actual operating conditions allowing a significant increase in product safety.

Online Demo with H2S Analyzer 320

During the product demonstration, you will gain many insights into how it works. You can follow the measuring process live and then discuss your questions with our experts.

The most important facts at a glance

| Pressure Range | up to 6 bar |

| Temperature range | +30 °C .. +200 °C |

| Measurement range H2S |

1 .. 1,000 ppm in vapor phase 1 .. 10,000 ppm in liquid phase |

| Sample amount per test | 2.5 / 5.0 / 10 ml |

H2S Analyzer data sheet

In the product data sheet you will find the exact specification as well as many data and options to help you decide on the H2S Analyzer 320.

WHY PSL?

We set new laboratory standards with our instruments

We have been developing, manufacturing and selling innovative laboratory instruments specifically for Flow Assurance for 25 years, setting new standards in the laboratory for professionals. We have been awarded innovation prizes for this. Our export quota of 90 % earned us the Export Oscar of Northern Germany.

PSL stands for reliability, quality and innovation. We are proud that the Big Five in the industry are among our satisfied customers.

WHAT WILL BE YOUR BENEFIT?

Reliable, high-quality instruments for your success

SAVE TIME IN EVERYDAY LAB WORK

with automated test cycles, cleaning procedures and easy-to-clean parts.

EASY TO USE

with a user-friendly, high-quality design for simple, correct and safe handling.

LONG LIFETIME MADE IN GERMANY

thanks to the sophisticated and robust design as well as the high-quality materials and manufacturing.

TRUSTED SERVICE - WORLDWIDE

with our online support, maintenance contracts and on-site service. We guarantee 20 years of repair service.

MEASURE LIKE INDUSTRY LEADERS

With innovative and advanced instruments, you can measure future-proof like the leading laboratories.

PLEASURE TO MEASURE

Our instruments make work a pleasure. They were developed together with the users.

I would like to know more about the instrument

You may also be interested in these products

Differential Dynamic Scale Loop

Benefit from the fully automated laboratory solution for analysing deposits in pipelines.

Mobile Differential Dynamic Scale Loop

Examine scale deposits in the pipelines directly on site at your customers in the process.

Pour Point Tester (PPT)

The portable Pour Point Tester measures the pour point of oils and oil products in accordance with ASTM D 5985, making it 30 times more accurate than ATSM D97 devices.