Pour Point Tester PPT 45150

Pour Points measure

The portable Pour Point Tester PPT 45150 by PSL Systemtechnik is a compact lab instrument to measure the no-flow point and calculate the pour point of oils and oil products. The PPT 45150 measures according the rotational method ASTM D5985.

Wide temperature range without external thermostats

With the rotational method used by the PPT 45150 the pour point (no-flow point) can be determined with an accuracy of ± 0,1 °C and a very good reproducibility. Resulting from the measurement of the no-flow point the pour pointacc. to ASTM D5985 can be determined.

Thanks to modern thermoelectrical heating/cooling modules you can measurewithout an external cryostat. A small amount of cooling water - with a water temperature of 8 °C - is sufficient to cover a temperature range of -45 °C to +150 °C (-49 °F to +302 °F).

Pour point measurements can be repeated up to nine times in succession. We recommend those multiple measurings to obtain statistical significant results and information about the sample's behaviour over time.

Low temperature - Pour Point Tester -55 up to +150 °C (-67 up to +302 °F)

Our Pour Point Tester is extendable with a cooling-water recooler for temperatures down to -55 °C (-67 °F) - a cost-effective alternative to cryostats with the same capacity.

Compact and transportable for worldwide use

Due to the compact design the Pour Point Tester requires only a small footprint and is transportable. All you need for operation is a cooling water- and a power supply. This permits a mobile operation of the Pour Point Tester 'in the field'. For a safe transport of the instrument and usual accessories a convenient trolley case is optionally available. At flights it can be taken as carry-on baggage if necessary.

The Pour Point Teste is equipped with a wide range voltage input so it can be operated all over the world.

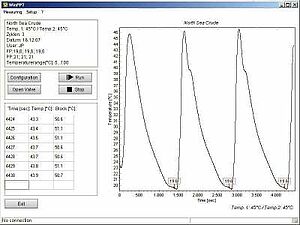

Fully automated test procedures with software

Up to 10 test configurations can be saved on the instrument in stand-alone mode. By connecting a PC to the Pour Point Tester and in combination with the PSL-software WinPPTthe instrument you can execute fully automated test runs. An unlimited number of test configurations can be saved and managed.

With WinPPT you can comfortably control your test runs, the temperature gradient is displayed in a temperature/time-graph and can be printed for documentation or saved in an Excel-compatible format for further evaluation.

The temperature gradientgives you additional information about the behaviour of the sample. First crystallisation-processes are as well observable as strong exothermal reactions.

With the calibration thermometer, available at PSL, the PPT can be calibrated once a year. Thus, you can always assure accurate measurement results. So an expensive maintenance service is obsolete and your maintenance costs are lowered.