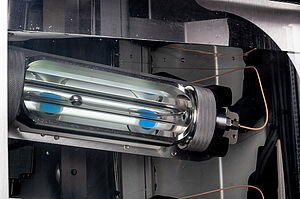

Sapphire Rocking Cell

Research of gas hydrates and inhibitors

The Sapphire Rocking Cell laboratory instrument tests the effectiveness and efficiency of gas hydrate inhibitors. These prevent or limit the formation of gas hydrates. Gas hydrates can form when natural gas is transported in the pipeline at low temperatures and high pressures, especially under deepwater conditions. For this purpose, the Sapphire Rocking Cell simulates two- and three-phase mixtures of natural gas, reservoir water and crude oil or condensates at pressures of up to 350 bar, as they typically form during pipeline transportation. The Sapphire Rocking Cell is used to test thermodynamic inhibitors (THI) and low-dosage inhibitors (LDHI) such as kinetic gas hydrate inhibitors (KHI) and anti-agglomerants (AA). The runtime of a ball is measured in the fully visible test cell made of sapphire glass. This test setup is ideal for anti-agglomerants. It provides essential information on the dispersion capacity and effectiveness of the inhibitor.

The situation: Natural gas production in the deep sea requires improved analysis capabilities

The oil and gas production in cold regions and in the subsea deepwater require the further development of Low-Dosage Hydrate Inhibitors (LDHI) as Kinetical Hydrate Inhibitors (KHI) and in particular the Anti-Agglomerants (AA).

The standard procedure to analyze gas hydrate inhibitors is to monitor the pressure and temperature profile.

The demand on laboratory equipment for research on Anti-Agglomerants is the possibility to verify if the transport of dispersed gas hydrate in the fluid flow of a pipeline can be ensured. Furthermore should the composed gas hydrate be directly observable. Using conventional lab equipment this can not be achieved. For approval of a new gas hydrate inhibitor in-field a detailed statistical check of effectiveness is necessary. The objection is to do the necessary amount of tests in the least possible time.

Our solution: Sapphire Rocking Cell with up to 20 test cells

The PSL Sapphire Rocking Cell offers an observation and measuring possibility as laboratory instrument attuned to the research on anti-agglomerants. The sapphire test cells are pressure-proof and can be used simultaneously in high amount.

Deepwater conditions can be simulated with the up to 200 bar (2,900 psi) covering test cells. Depending on the setup it is possible to use up to 20 sapphire cells at the same time. With the ball run-time measurement the pumpability of the dispersed gas hydrate can be tested and conclusions about viscosity changes can be drawen. The design based on Champion Technologies Sapphire Rocking Cell.

The key feature: The test cells are transparent and the entire sample chamber can be viewed

The sapphire test cells are completely transparent. The whole sample chamber is visible for close observation of the samples behaviour and the structure of the composed gas hydrates. In addition the tests can be recorded by a video camera. For the first time it is possible to observe if hydrates are gathering or compacting on less turbulent areas. Furthermore the interaction of LDHIs and different additional substances like corrosion inhibitors (CI), asphaltene inhibitors (AI), wax inhibitors (WI) or scale inhibitors (SI) are accessible by experimental data. Free water or oil phases are detectable.

Your benefit: You save at least 50% of the development and testing time

With the Sapphire Rocking Cell you can save up to 50 % of your development and measuring times compared to the actually used test methods. Your project costs reduce accordingly.

Testing of Anti-Agglomerants with the Sapphire Rocking Cell will get you much more accurate results. It fulfills the needed stringent conditions for evaluate inhibitors for deepwater application. Anti-Agglomerants can be optimized and adjusted to your application and actual operating conditions which allows a significant increase in product safety.

The advantages of the Sapphire Glass Rocking Cell at a glance

- Completly visible sapphire test cell for optimization of inhibitors

- Ball run-time measurement enables research on anti-agglomerants

- Up to 20 test cells afford savings up to 50% on development and project times

- Stringent test conditions for improvement on product safety on deepwater application

- Plug-and-Play concept

- Three model types available and customizing of each model possible

The measuring principle simulates pipeline conditions

The measuring principle of the Rocking Cell is based on the constant tilting (rocking) of temperature-controlled, pressurized test cells (rocking cells). By tilting a inserted ball rolls through the entire length of the test cell and mixes the contained fluid-gas mixture. The ball movement induces strong shear forces and turbulences inside the test cell which simulated the conditions inside a pipeline. A typical experiment can be divided into the three phases flowing conditions, shut-in and restart flowing conditions.

The test is programmed in the software and then runs automatically

For a test the cell are filled with sample fluid (water, oil or condensate) and the desired amount of inhibitor. The cells are then cooled to the default test temperature. Each single cell can then be filled with an individual pressure up to 200 bar (2,900 psi) afterwards. The up to 20 test cells are mounted on a movable axle inside of a bath with cooling liquid.

All test parameters like e.g. rocking angle, rocking rate and time of test periods can be scheduled via software, so a programmed experiment can be started with a simple push on a button.

Ball run-time is determined by induction sensors, this ensures an accurate time measurement even in dark and opaque fluids. A camera can be controlled via software for automatic recording of pictures and videos at any time of the experiment.

After test completion cleaning and refilling is easy and done fast. The cooling bath is lowered, the test cells are then easily accessible and can be removed from their mountings.

Four different models - for your requirement

- RCS 2 with 2 test cells: with extended 180° rocking angle

- RCS 6 with 6 test cells: optimized for the fume hood

- RCS 8 with 8 test cells: optimized for 2 blank tests and 3 duplicate tests

- RCS 20 with up to 20 test cells: for large demand

The Sapphire Rocking Cell can be adapted to your needs to match the optimal setting for your application.

![[Translate to Englisch:] Sapphire Rocking Cell RCS6 Cells moving [Translate to Englisch:] Sapphire Rocking Cell RCS6 Cells moving, Hydrate Testing](/fileadmin/_processed_/3/9/csm_DSCF9725_fd434404e2.jpg)